- Ceramic Bearings

- Ceramic Balls and Beads

- Cutting Tools

- Ceramic Rings

- Porous Ceramic

- Structure / Components

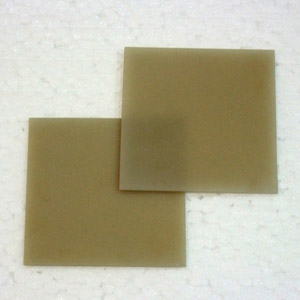

- AlN Ceramic

- Ceramic Pipe / Tube

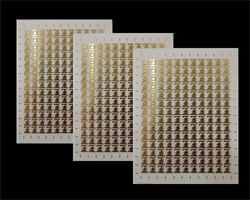

- Ceramic Substrates

Technical factors of Aluminum Nitride (AlN) Substrate products

Item |

Fine |

Excellent (edge grind) |

|

dimension |

Lengt h ≦ 300, width ≦ 120, Thickness0.20~1.20 |

||

Length tolerance |

Thickness ≦ 0.63 |

+ 0.15 -0.05 |

+0.10 -0.05 |

0.6 3 < Thickness ≦ 0.76 |

+0.20 -0.05 |

||

0.76 < Thickness ≦ 1.0 |

+ 0.15 -0.05 |

||

Thicknes s tolerance |

± 7%, and NL T ± 0.05 |

||

Scribing to scribing tolerance |

± 0.05 |

||

Minimum scribing width |

0.10 |

||

Hole dimension |

Minimum diameter of round hole is 0.02; minimum side length of the other hole is 0.20 |

||

Edge-to-scribed line(the middle of hole)tolerance |

Thickness¡≦ 0.63 |

+ 0.15 -0.05 |

± 0.05 |

0.6 3 < Thickness ≦ 0.76 |

+ 0.20 -0.05 |

± 0.05 |

|

0.76 < Thickness ≦ 1.0 |

+ 0.25 -0.05 |

± 0.08 |

|

Holes tolerance |

Φ 0.2~2.0 |

± 0.05 |

± 0.05 |

Φ 2.0~10.0 |

± 0.10 |

± 0.10 |

|

Φ 10.0 or more |

± 0.8% |

± 0.8% |

|

Center-to-center distance of Holes tolerance |

± 0.05 |

± 0.05 |

|

Minimum distance of hole-to-hole and hole-to-edge |

≧ 1.2times thickness of the substrate,and NLT 1.0m m |

||

Difference between entry diameter and exit diameter of a hole |

≦ 8%thickness of the substrate |

||

Camber |

≦ 0.05/25.4(long side),NLT 0.05m m |

||

Parallel degree/vertical degree |

0.2% of the longest side |

||

Technical factors of Aluminum Nitride Subtracts

Property content |

Property index |

Density (kg/m 3 ) |

≧ 3.26 |

Water absorption(%) |

0 |

Linear expansion coefficient [RT -50 0 oC ](10 -6 mm / oC ) |

4.4 |

Bulk resistivity ( Ω cm ) |

≧ 10 14 |

Dielectric constant[ 1M H z ] |

9 |

Dissipation factor[ 1M H z ] |

3 ≧ 10 -4 |

Dielectric strength (KV/mm) |

15 |

Flexural strength (MPa) |

≧ 330 |

Thermal conductivity[ 20 oC ] (W/ m - k ) |

≧ 170 |

Surface finish Ra( μ m) |

0.25~0.5 |

Camber (~/25 ) |

0.05 |

color |

Nattierblue |

Appearance |

Density |