- Ceramic Bearings

- Ceramic Balls and Beads

- Cutting Tools

- Ceramic Rings

- Porous Ceramic

- Structure / Components

- AlN Ceramic

- Ceramic Pipe / Tube

- Ceramic Substrates

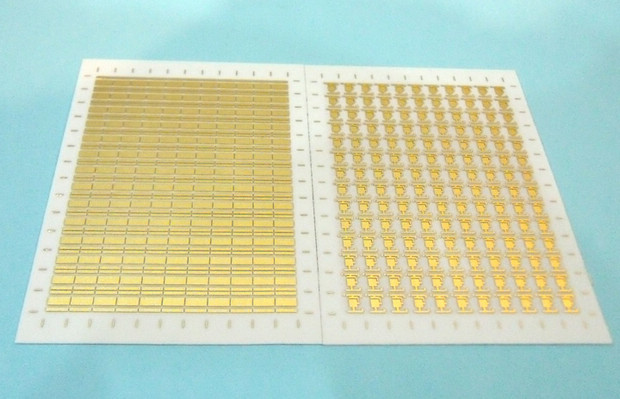

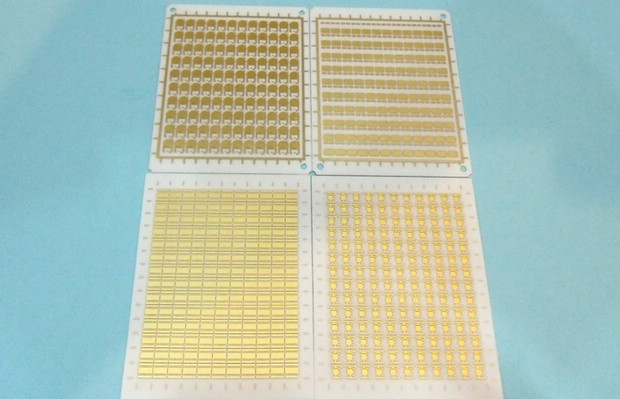

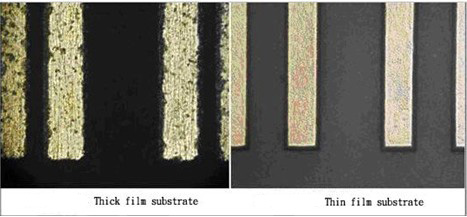

Difference between thin & thick film patterns |

|

Thin Film Patterns |

Thick Film Patterns |

Better pattern accuracyof +/-1% |

Normal Pattern accuracyof +/-10% |

Higher surface roughness of <0.3um |

Poor surface roughness of 1~3um |

Goodsurface adhesion in both Al2O3 and AlN |

Good surface adhesion in Al2O3 but poor adhesion in AlN |

Good alignment accuracy |

Poor alignment accuracy |

Higher materialstability (Cu layer) |

Normal materialstability (Ag and glass mixture) |

Conductivity Comparison of Various Materials |

|

Materials |

Conductivity(W/mK) |

FR4 |

0.2 |

Al2O3 |

17-27 |

Aluminium Nitride(AlN) |

160-230 |

Gold |

315 |

Silver |

425 |

Copper |

398 |

Ceramic metallized: Ti/W,gold(Au), sliver(Ag), Copper(Cu), nickel(Ni)¡K others & produce final circuit

- coating:0.03um to 5mil

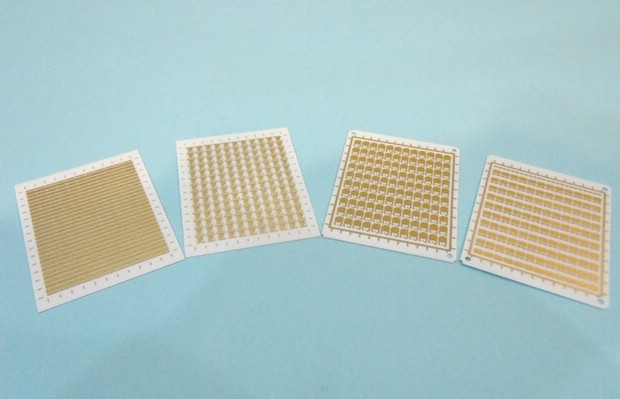

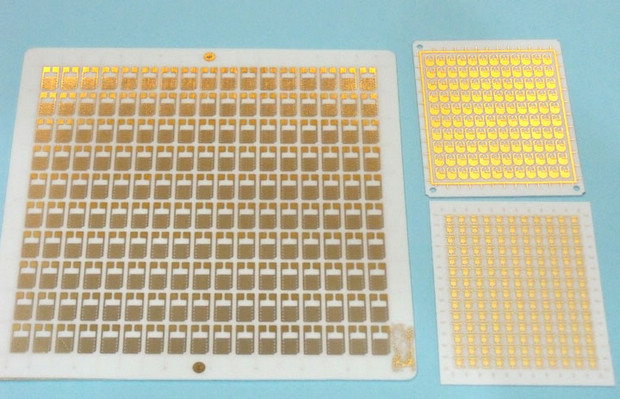

- Ceramic Metallized substrate:

- Al2O3 substrate metallized

- AlN substrate metallized

- Silicon wafer metallized

- LED heat-dissipation ceramic substrate:

- LED Al2O3 thin film substrate

- LED Al2O3 thick film substrate

- LED AlN thin film heat-dissipation substrate

- Flip chip substrate

- The integration of the thin film,thick film,electrode plating and electroless plating processes:

Application:

1. High Power LED ceramic substrate

2. Microwave (Wireless Communication & Radar)

3. Semiconductor Process Equipment

4. Solar Cell

5. Hybrid Electric Vehicles

6. Flip chip/eutectic substrate

7. Sensor ceramic substrate