- Ceramic Bearings

- Ceramic Balls and Beads

- Cutting Tools

- Ceramic Rings

- Porous Ceramic

- Structure / Components

- AlN Ceramic

- Ceramic Pipe / Tube

- Ceramic Substrates

|

|

These ceramic inserts are the high precision dam-bar cutter for IC packaging. It lasts up to 2 times of the carbide cutting tools. It will save the total running cost of more than 40% including reduction of downtime and maintenance.

Comparison of Ceramic and Carbide Cutters: Click Here

Properties

- Hardness:

- Vickersn 13.5 GPa

- 210 Ksi (1440 MPa)

- 8 MPa m ½

- 4 Point bend strength

- Fracture Toughness

- Fully Dense, Non – Porous

- Single Phase

- Fine gain size (< 1 micron)

- Low coefficient of friction

- Light weight – less than half the density of carbide

Benefits

- Extremely low wear rates compared to the leading carbide grade – up to 600% longer tool life between resharpenings

- Maximize press up-time and strokes between resharpenings

- Reduce scrap up to 80%

- Resists metal pick-up - fully dense, non-porous body

- Corrosion resistant – no binder system to be degraded

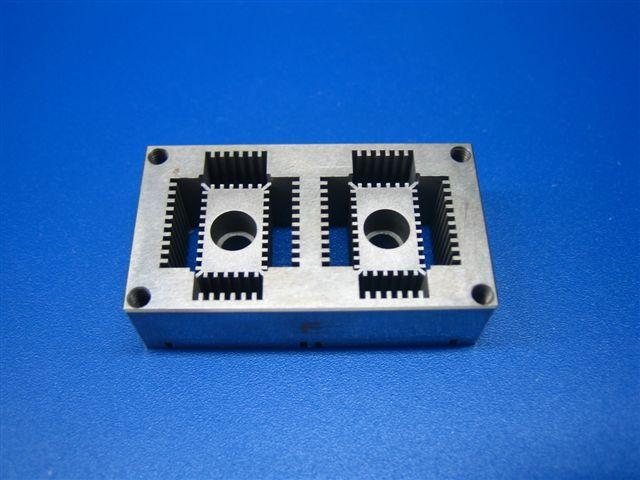

The Trim/Form high precision die set desgined and made for our customers.

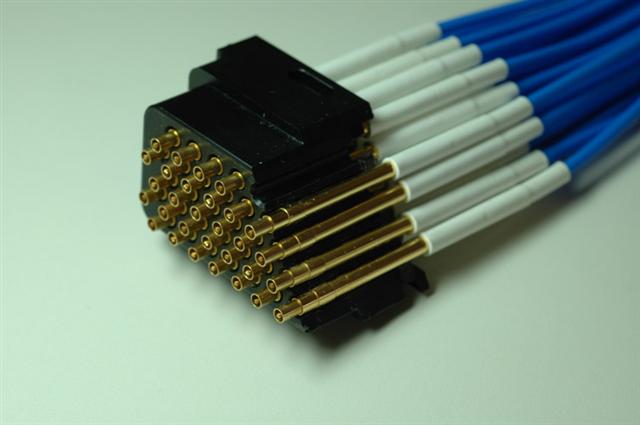

High precision pogo pin holder. Dimensioin tolerance of the pins could be +/- 1 micron.